-

-

미래를 여는 특장차 선두기업특장차 전문 집게차, 크레인 신규 및 중고판매

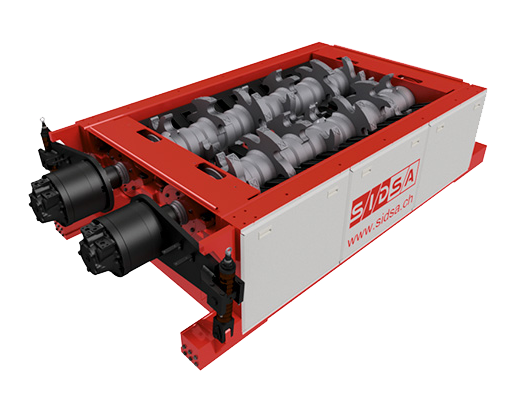

SISDA-SERIES XLC

Primary shredders. Hook shredders. Even mobile.

XLC PRIMARY SHREDDERS ARE KNOWN AS THE STURDIEST AND THE MOST RELIABLE MACHINES.

They guarantee high throughput and very good productivity with low maintenance and operational costs.

Our primary shredders are suitable for a wide variety of products such as: industrial, bulky, municipal and hazardous waste.

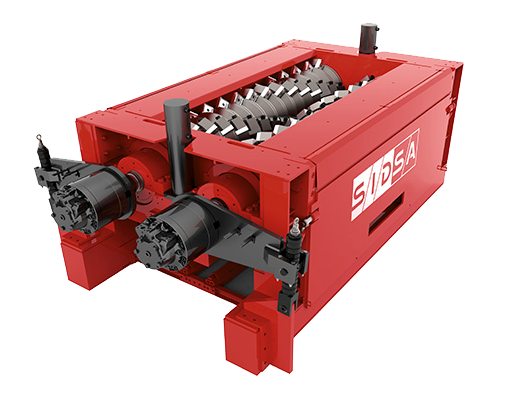

SISDA-SERIES XLF

Fine shredders. High torque.

FINE SHREDDERS CONSIST OF ONE OR TWO SHAFTS EACH DRIVEN BY A SLOW-SPEED HIGH TORQUE MOTOR.

The different powers are developed by two hydraulic power packs. Each hydraulic unit drives one shaft.

Electric high torque drives are also available

GEP ECOTECH-GD SERIES

Primary shredders. Hook shredders. Even mobile.

GD series double-shaft shearing crusher uses the principle of shearing and tearing between two relatively rotating cutters to crush materials. Using "double motor + double planetary reducer", the power is strong and the operation stability is high. It is often used in environmental protection fields such as municipal solid waste disposal, resource regeneration, waste incineration pretreatment and so on. The equipment has the characteristics of low speed, large torque, large shearing force, good tearing effect, low noise and good stability.

GEP ECOTECH-GE SERIES

Fine shredders. High torque.

GE series Europe type fine shredder is a new upgraded version of fine shredder. It adopts single-shaft "double motor + double reducer" drive design to provide large shearing force and ensure high shredding output. Usually used in the fine shredding of solid waste, the material can be processed to a smaller size at one time. It is widely used in resource regeneration, RDF (domestic waste derivative fuel) production, plastic recycling, garbage treatment and other fields. It has the characteristics of small discharging granularity, replaceable screen, wide material applicability and high efficiency.